The Moss Commitment

We’re committed to outstanding service, world class products, continuous improvement, sustainability and a positive work environment.

We understand – the Experience is everything – the experience attendees recognize visiting our installations and the experience our customers value in a collaborative partnership. We strive to provide a “total customer solution” that includes the industry’s best products and activations consistently delivered on time, to the right location, every time. We believe that delivering exceptional value to our customers makes it possible to provide excellent returns to our employees, communities, and shareholders.

We believe that the natural world is the most valuable legacy we can leave for future generations. Doing business sustainably means we consider the environment when making supply chain and manufacturing decisions. We actively reduce, recycle, reuse and take action to improve the quality of the environment.

The Moss workplace is a place for growth, where everyone can both teach and learn. Here, we value a positive work environment, embrace diversity, and support equal opportunity for individual growth. Our commitment to community is a principle of how we do business.

If this sounds like the kind of company you would like to be part of, see current jobs. If this sounds like the kind of company you would like to do business with, contact us.

Our headquarters and domestic manufacturing is located in Franklin Park, Illinois and international manufacturing locations are in Lennestadt, Germany, Poznań, Poland, and Saint Neots, United Kingdom.

OUR STORY

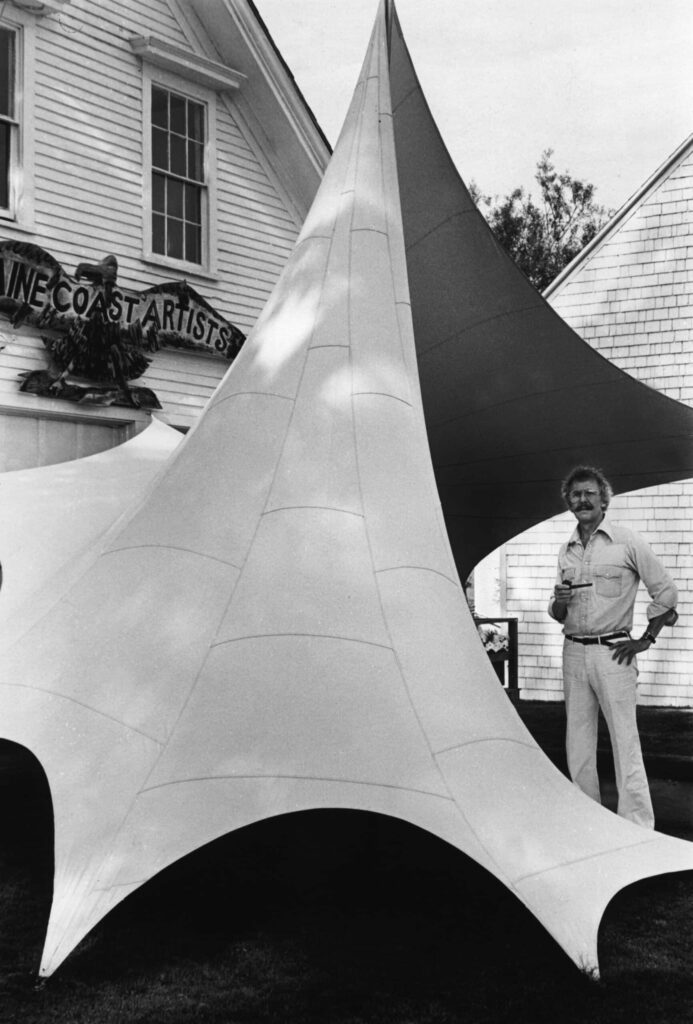

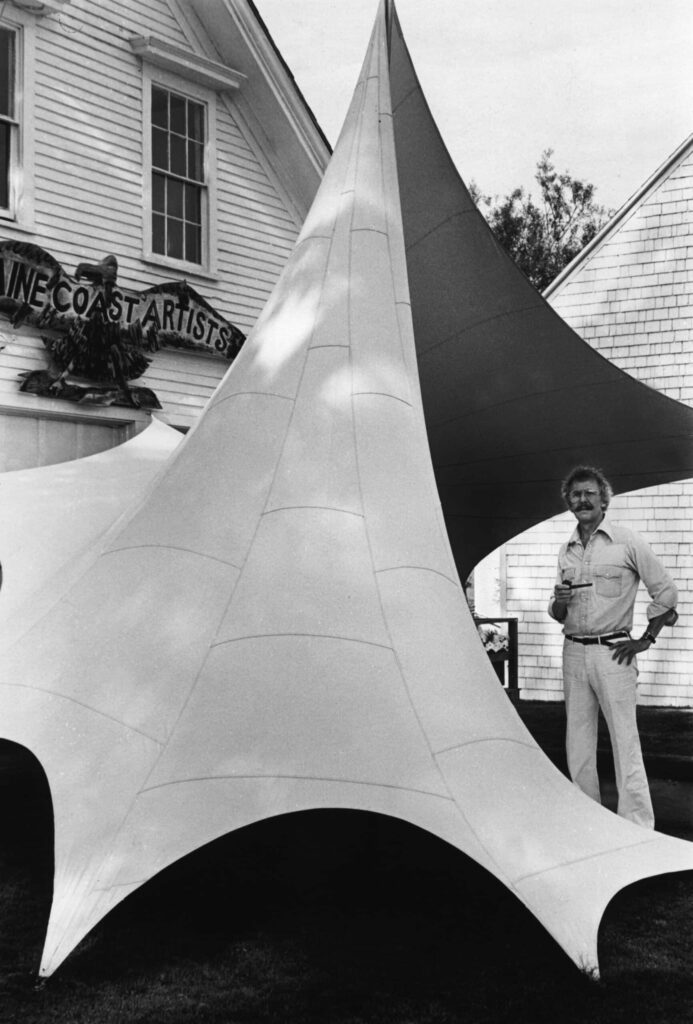

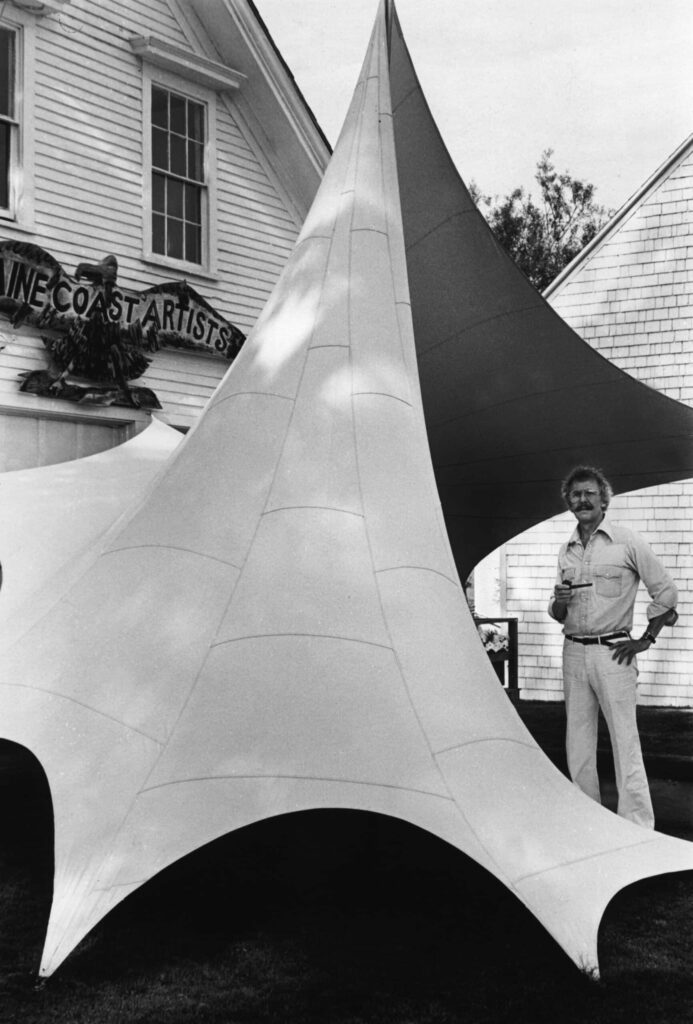

1955

FABRIC INNOVATION

Our history begins with a 20th-century visionary: Bill Moss. An artist and outdoors-man who was passionate about industrial design and “tensioned fabric.” Bill designed and patented the first “pop-up” tent in 1955.

1983

SHOW STOPPER

We brought our expertise of curvilinear designs in lightweight fabric and frame to the Outdoor Retailer Show as a backdrop for our products, causing a stir in the industry as exhibitors recognized the advantages of a lightning-fast assemble and dismantle fabric structure solution.

2002

ONWARD AND UPWARD

A passion for innovation continued to move us ahead. We increased our manufacturing capabilities by acquiring Exhibit Architecture in 2002, located just outside of Chicago, and in 2006 opened our first rental depot in Las Vegas.

Harley Davidson 100th Anniversary Celebration

2007

GREAT MINDS THINK ALIKE

We partnered with Nichols Inc., A company with a history of pioneering fabric printing. The combination of Nichols’ premier printing and our engineering in custom tensioned fabric structures set the stage to increase production capacity and product offerings significantly.

2010

SERVICE & PRODUCT EXPANSION

Our portfolio expansion continued with the purchase of Pink Inc., A well-known premier brand in the event décor industry. Pink Inc. added a layer of creative and unique event solutions to our growing list of capabilities.

2011

CONTINUED ADVANCEMENT

Flying Colors, located in Berkeley, CA., was added to our expanding family in 2011, creating additional market opportunities. Flying Colors was renowned in the sports industry as a top provider of design, program management, and installation for venue and event branding.

Denver Broncos Field Wall

2014

KNOWLEDGE DIVERSIFICATION

We added Andres Imaging & Graphics, a recognized digital & print fabrication leader in sporting, corporate, and retail branded environments. Andres provided a layer of cutting-edge technology with capabilities like direct print from transparencies, dye transfer prints from scanner separations, and the first electrostatic print transfers onto materials never printed before.

2015

GLOBAL SOLUTIONS PROVIDER

International production began with the acquisition of Germany’s Marx+Moschner, a European tension fabric leader who, like Moss, had innovatively served retail and trade show customers for over 30 years. The strategic growth comes with increased demand from retail and exhibit markets seeking our solutions worldwide.

Carola’s Garden Asisi Panorama

2017

GLOBAL PRINT NETWORK

We invested in new print technology to offer a consistent graphic experience on three continents. Durst’s premium printers combined with our best-in-class materials, and automated preproduction processes to provide the best quality, lead time and capacity at incredibly competitive pricing.

Moss Europe Print Room

2018

INTERNATIONAL GROWTH

We opened in Changzhou, China, in a newly built facility inland from Shanghai. At more than 80,000 sq ft, Changzhou serves as an excellent base to support the growing Asian market.

APPPEXPO Shanghai, China

2020

ULTIMATE PARTNERSHIP

Our new global headquarters and operations facility in Franklin Park, Illinois opened for business. This state-of-the-art 180,000+ sq. ft. space accommodates all U.S. A. operations and brings together our core capabilities, expertise, and production volume under one roof.

Corporate Headquarters Production Floor

2021

COMMITMENT TO SUSTAINABILITY

We unveiled our Environmental Sustainability Policy to ensure sustainability is ingrained in our day-to-day operations and solidify ourselves as a responsible partner to our clients. In 2021 our global operations achieved EcoVadis Silver Medal Status. Our environmental commitment includes:

- Reducing emissions of greenhouse gases (GHGs).

- Improving the efficiency of resources used.

- Bringing to market Eco-friendly products and services.

- Minimizing waste developed in day- to-day operations.

2023

European Expansion

Our acquisition of MarcoArt in the United Kingdom and the opening of a new facility in Poznań, Poland, accelerates the creation of a global footprint of production facilities which allows us to serve our clients with increased capacity and faster turnaround times across the European market.

OUR STORY

1955

FABRIC INNOVATION

Our history begins with a 20th century visionary: Bill Moss. An artist and outdoors-man who was passionate about industrial design and “tensioned fabric.” Bill designed and patented the first “pop-up” tent in 1955.

1983

SHOW STOPPER

We brought our expertise of curvilinear designs in lightweight fabric and frame to the Outdoor Retailer Show as a backdrop for our products, causing a stir in the industry as exhibitors recognized the advantages of a lightning-fast assemble and dismantle fabric structure solution.

2002

ONWARD AND UPWARD

A passion for innovation continued to move us ahead. We increased our manufacturing capabilities by acquiring Exhibit Architecture in 2002, located just outside of Chicago, and in 2006 opened our first rental depot in Las Vegas.

Harley Davidson 100th Anniversary Celebration

2007

GREAT MINDS THINK ALIKE

We partnered with Nichols Inc., A company with a history of pioneering fabric printing. The combination of Nichols’ premier printing and our engineering in custom tensioned fabric structures set the stage to increase production capacity and product offerings significantly.

2010

SERVICE & PRODUCT EXPANSION

Our portfolio expansion continued with the purchase of Pink Inc., A well-known premier brand in the event décor industry. Pink Inc. added a layer of creative and unique event solutions to our growing list of capabilities.

2011

CONTINUED ADVANCEMENT

Flying Colors, located in Berkeley, CA., was added to our expanding family in 2011, creating additional market opportunities. Flying Colors was renowned in the sports industry as a top provider of design, program management, and installation for venue and event branding.

Denver Broncos Field Wall

2014

KNOWLEDGE DIVERSIFICATION

We added Andres Imaging & Graphics, a recognized digital & print fabrication leader in sporting, corporate, and retail branded environments. Andres provided a layer of cutting-edge technology with capabilities like direct print from transparencies, dye transfer prints from scanner separations, and the first electrostatic print transfers onto materials never printed before.

2015

GLOBAL SOLUTIONS PROVIDER

International production began with the acquisition of Germany’s Marx+Moschner, a European tension fabric leader who, like Moss, had innovatively served retail and trade show customers for over 30 years. The strategic growth comes with increased demand from retail and exhibit markets seeking our solutions worldwide.

Carola’s Garden Asisi Panorama

2017

GLOBAL PRINT NETWORK

We invested in new print technology to offer a consistent graphic experience on three continents. Durst’s premium printers combined with our best-in-class materials, and automated preproduction processes to provide the best quality, lead time and capacity at incredibly competitive pricing.

Moss Europe Print Room

2018

INTERNATIONAL GROWTH

We opened in Changzhou, China, in a newly built facility inland from Shanghai. At more than 80,000 sq ft, Changzhou serves as an excellent base to support the growing Asian market.

APPPEXPO Shanghai, China

2020

ULTIMATE PARTNERSHIP

Our new global headquarters and operations facility in Franklin Park, Illinois opened for business. This state-of-the-art 180,000+ sq. ft. space accommodates all U.S. A. operations and brings together our core capabilities, expertise, and production volume under one roof.

Corporate Headquarters Production Floor

2021

COMMITMENT TO SUSTAINABILITY

We unveiled our Environmental Sustainability Policy to ensure sustainability is ingrained in our day-to-day operations and solidify ourselves as a responsible partner to our clients. In 2021 our global operations achieved EcoVadis Silver Medal Status. Our environmental commitment includes:

- Reducing emissions of greenhouse gases (GHGs).

- Improving the efficiency of resources used.

- Bringing to market Eco-friendly products and services.

- Minimizing waste developed in day- to-day operations.

2023

EuROPEAN EXPANSION

Our acquisition of MarcoArt in the United Kingdom and the opening of a new facility in Poznań, Poland, accelerates the creation of a global footprint of production facilities which allows us to serve our clients with increased capacity and faster turnaround times across the European market.

1955

FABRIC INNOVATION

Our history begins with a 20th century visionary: Bill Moss. An artist and outdoors-man who was passionate about industrial design and “tensioned fabric.” Bill designed and patented the first “pop-up” tent in 1955.

1983

SHOW STOPPER

We brought our expertise of curvilinear designs in lightweight fabric and frame to the Outdoor Retailer Show as a backdrop for our products, causing a stir in the industry as exhibitors recognized the advantages of a lightning-fast assemble and dismantle fabric structure solution.

2002

ONWARD AND UPWARD

A passion for innovation continued to move us ahead. We increased our manufacturing capabilities by acquiring Exhibit Architecture in 2002, located just outside of Chicago, and in 2006 opened our first rental depot in Las Vegas.

Harley Davidson 100th Anniversary Celebration

2007

GREAT MINDS THINK ALIKE

We partnered with Nichols Inc., A company with a history of pioneering fabric printing. The combination of Nichols’ premier printing and our engineering in custom tensioned fabric structures set the stage to increase production capacity and product offerings significantly.

Del Monte Foods

2010

SERVICE & PRODUCT EXPANSION

Our portfolio expansion continued with the purchase of Pink Inc., A well-known premier brand in the event décor industry. Pink Inc. added a layer of creative and unique event solutions to our growing list of capabilities.

MTV Movie Awards

2011

CONTINUED ADVANCEMENT

Flying Colors, located in Berkeley, CA., was added to our expanding family in 2011, creating additional market opportunities. Flying Colors was renowned in the sports industry as a top provider of design, program management, and installation for venue and event branding.

Denver Broncos Field Wall

2014

KNOWLEDGE DIVERSIFICATION

We added Andres Imaging & Graphics, a recognized digital & print fabrication leader in sporting, corporate, and retail branded environments. Andres provided a layer of cutting-edge technology with capabilities like direct print from transparencies, dye transfer prints from scanner separations, and the first electrostatic print transfers onto materials never printed before.

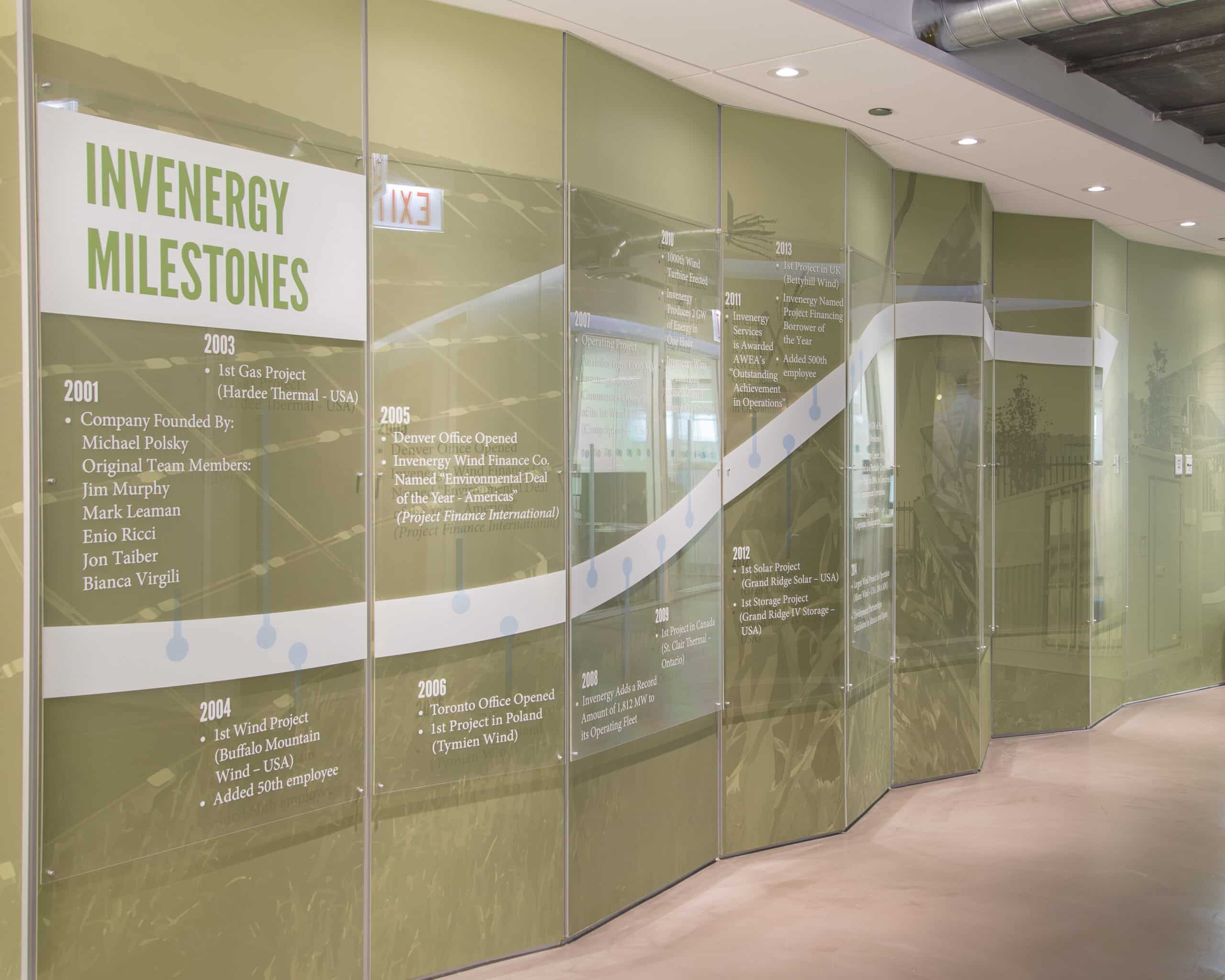

Buckeye Library

Invenergy Chicago Office

Burger King Rollout

2015

GLOBAL SOLUTIONS PROVIDER

International production began with the acquisition of Germany’s Marx+Moschner, a European tension fabric leader who, like Moss, had innovatively served retail and trade show customers for over 30 years. The strategic growth comes with increased demand from retail and exhibit markets seeking our solutions worldwide.

Carola’s Garden Asisi Panorama

2017

GLOBAL PRINT NETWORK

We invested in new print technology to offer a consistent graphic experience on three continents. Durst’s premium printers combined with our best-in-class materials, and automated preproduction processes to provide the best quality, lead time and capacity at incredibly competitive pricing.

Moss Europe Print Room

2018

INTERNATIONAL GROWTH

We opened in Changzhou, China, in a newly built facility inland from Shanghai. At more than 80,000 sq ft, Changzhou serves as an excellent base to support the growing Asian market.

APPPEXPO Shanghai, China

2020

ULTIMATE PARTNERSHIP

Our new global headquarters and operations facility in Franklin Park, Illinois opened for business. This state-of-the-art 180,000+ sq. ft. space accommodates all U.S. A. operations and brings together our core capabilities, expertise, and production volume under one roof.

Corporate Headquarters Production Floor

2021

COMMITMENT TO SUSTAINABILITY

We unveiled our Environmental Sustainability Policy to ensure sustainability is ingrained in our day-to-day operations and solidify ourselves as a responsible partner to our clients. In 2021 our global operations achieved EcoVadis Silver Medal Status. Our environmental commitment includes:

- Reducing emissions of greenhouse gases (GHGs).

- Improving the efficiency of resources used.

- Bringing to market Eco-friendly products and services.

- Minimizing waste developed in day- to-day operations.

Corporate Headquarters Production Floor

2023

EUROPEAN EXPANSION

Our acquisition of MarcoArt in the United Kingdom and the opening of a new facility in Poznań, Poland, accelerates the creation of a global footprint of production facilities which allows us to serve our clients with increased capacity and faster turnaround times across the European market.

Poznań, Poland Facility

Saint Neots, United Kingdom Facility