OUR CAPABILITIES

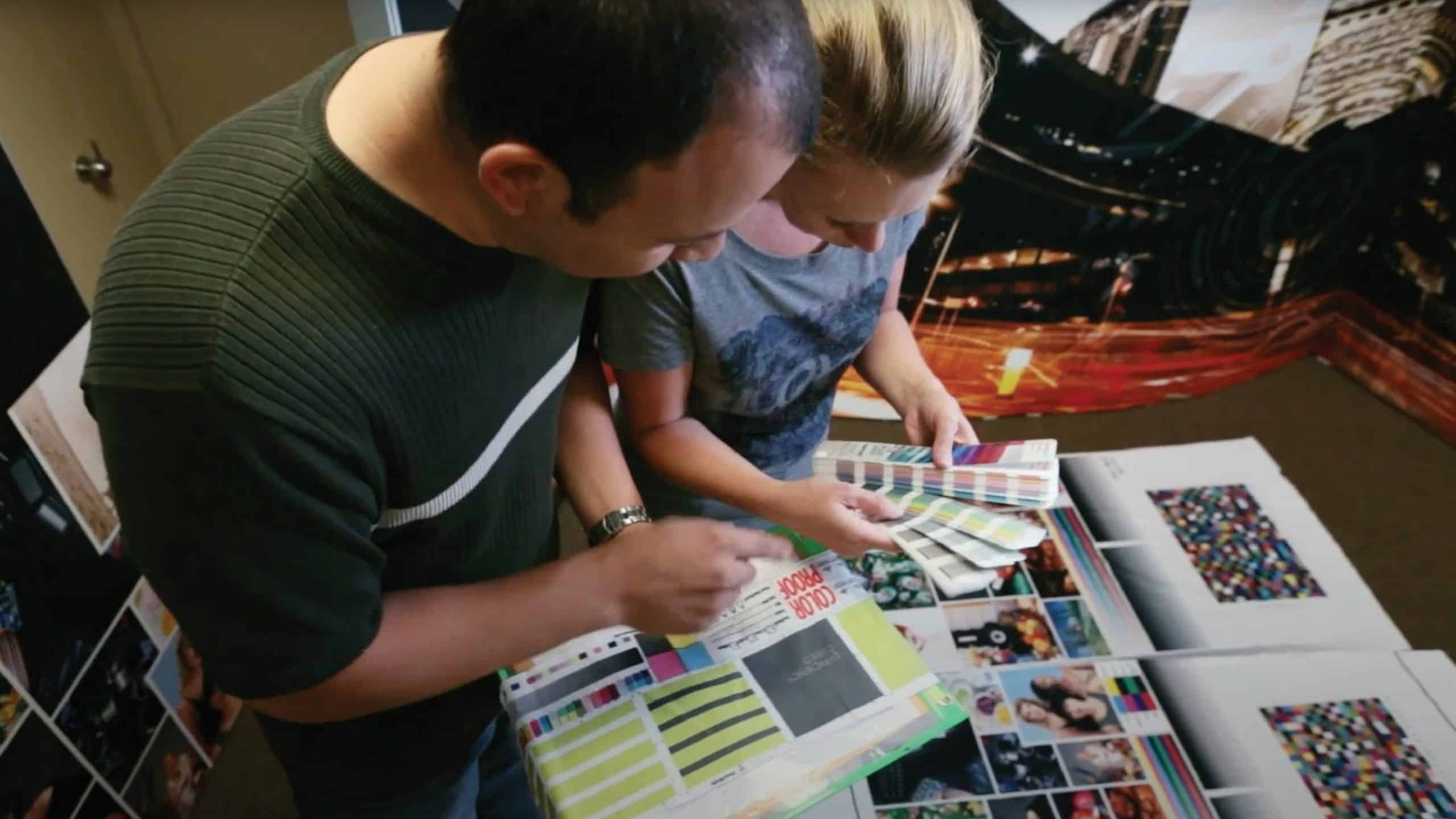

Color Matching

Finishing

LED Lighting

Metal Fabrication

Mixed Media Fabrication

Paint

Powder Coating

Routing

Sewing

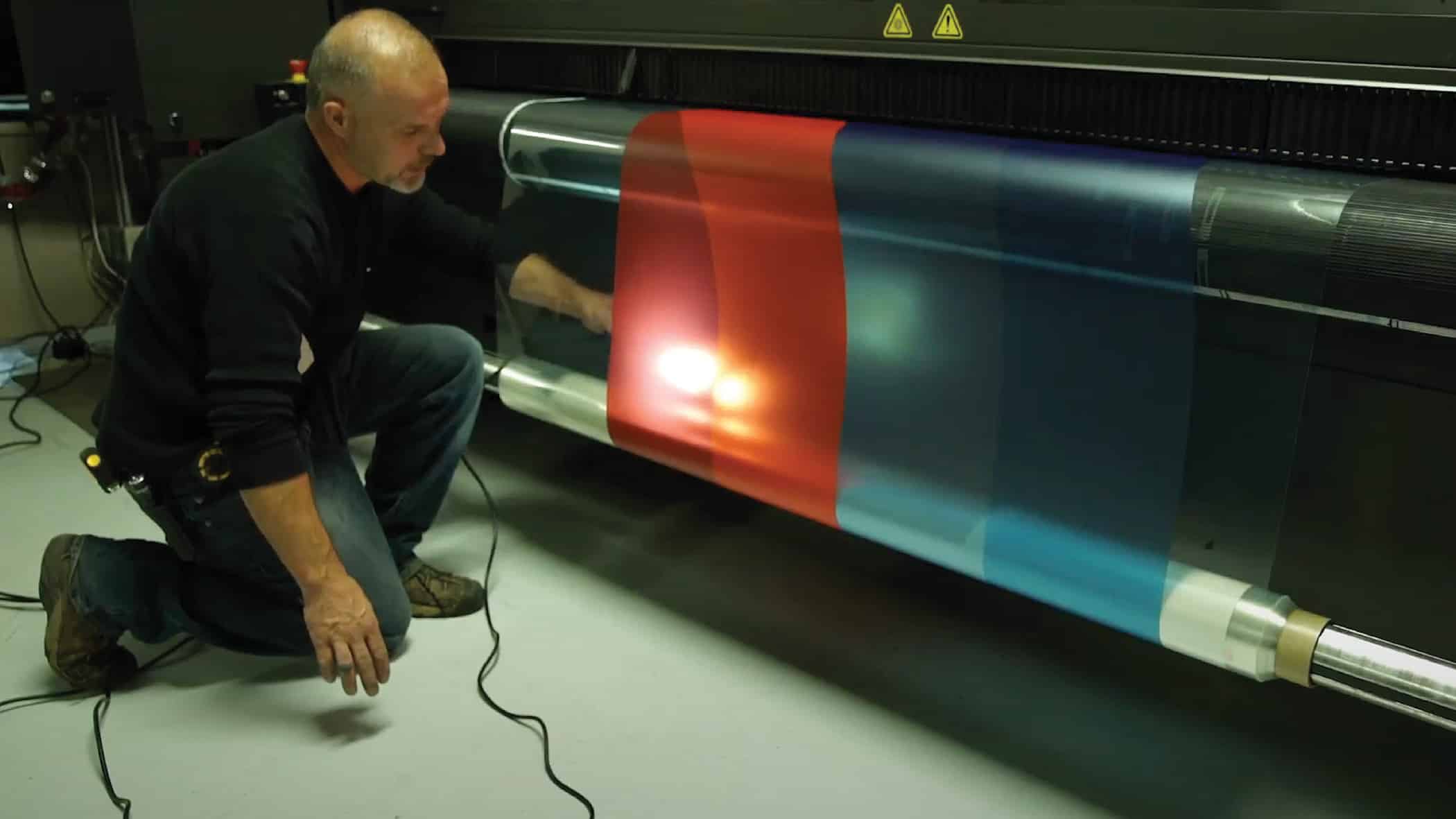

Specialty Textiles

Tension Fabric Structures

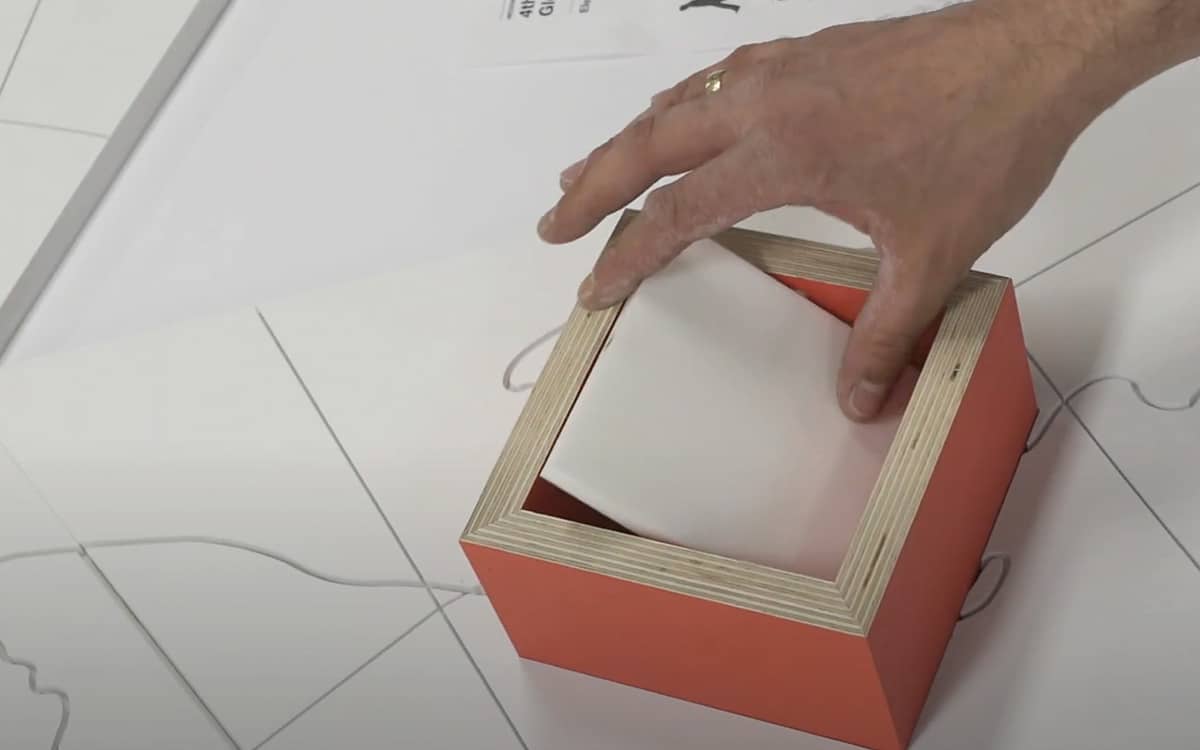

Wood Fabrication

Laser cutting

Specialty Sourcing

OUR CAPABILITIES

Tension Fabric Structures

Mixed Media Fabrication

Finishing

Sewing

LED Lighting

Specialty Textiles

Metal Fabrication

Wood Fabrication

Paint

Powder Coating

Color Matching

Specialty Sourcing

OUR PROCESS

- SOLUTIONS DESIGN+

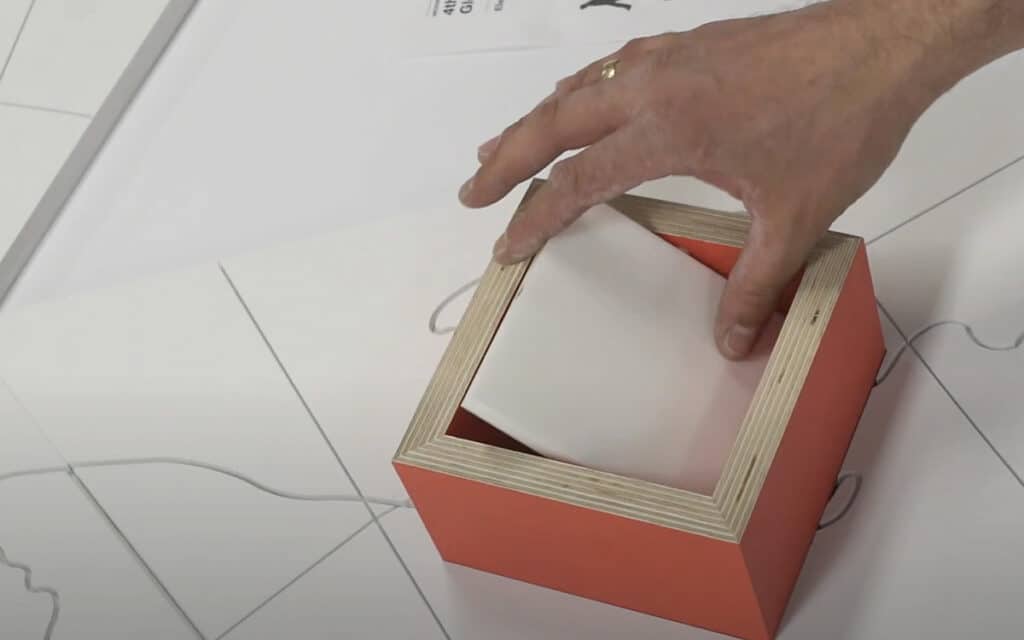

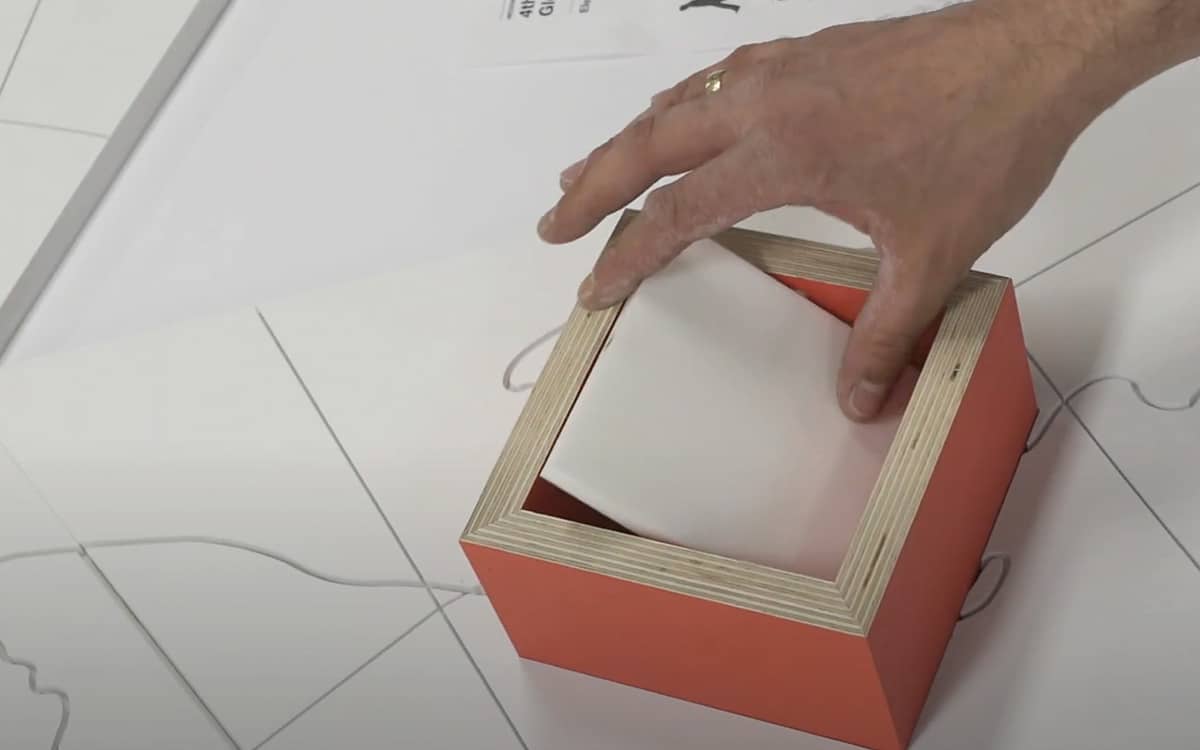

- PROTOTYPING+

- DESIGN FOR MANUFACTURING+

- PRE-PRODUCTION+

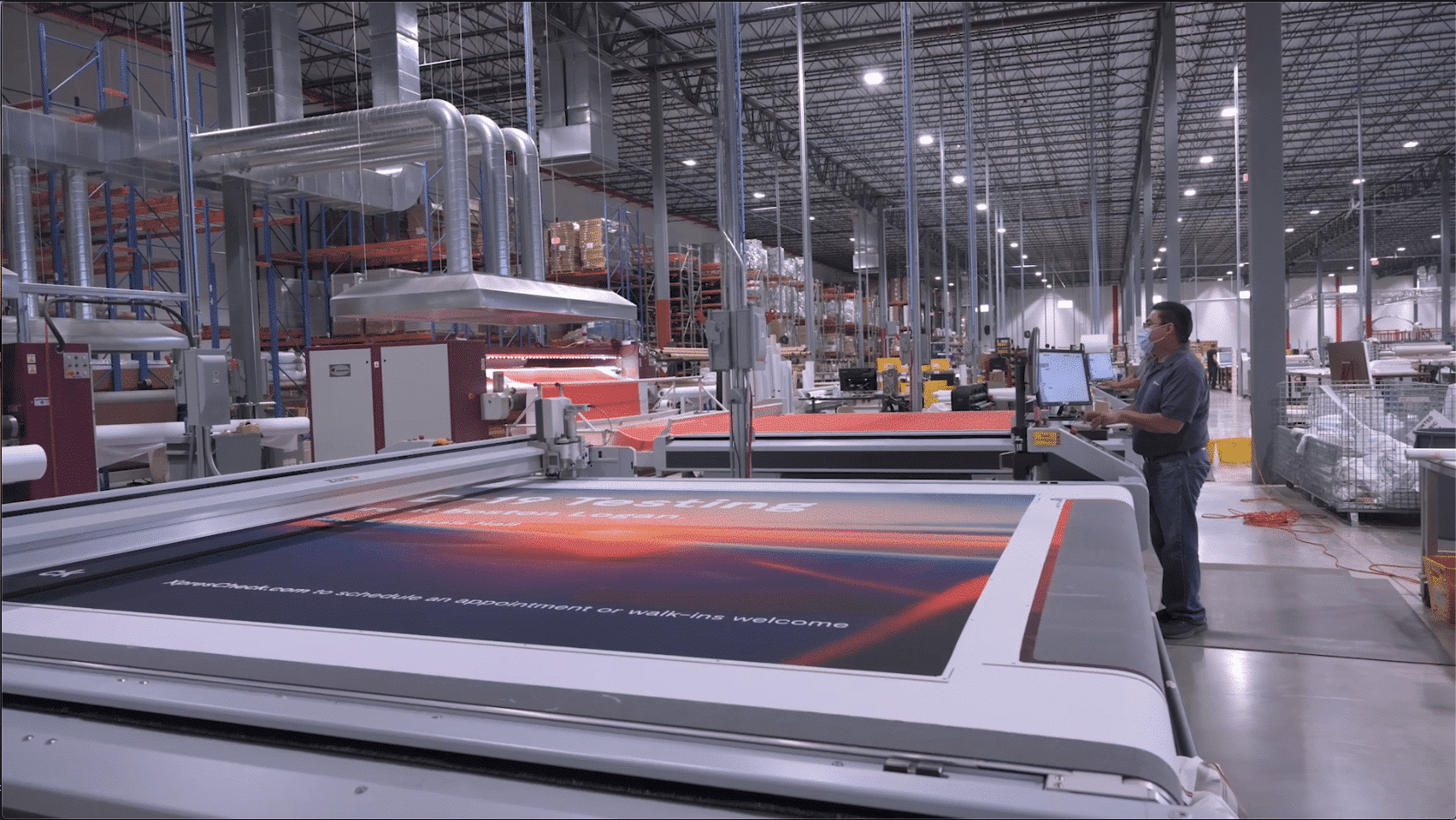

- MANUFACTURING+

- INSTALLATION+

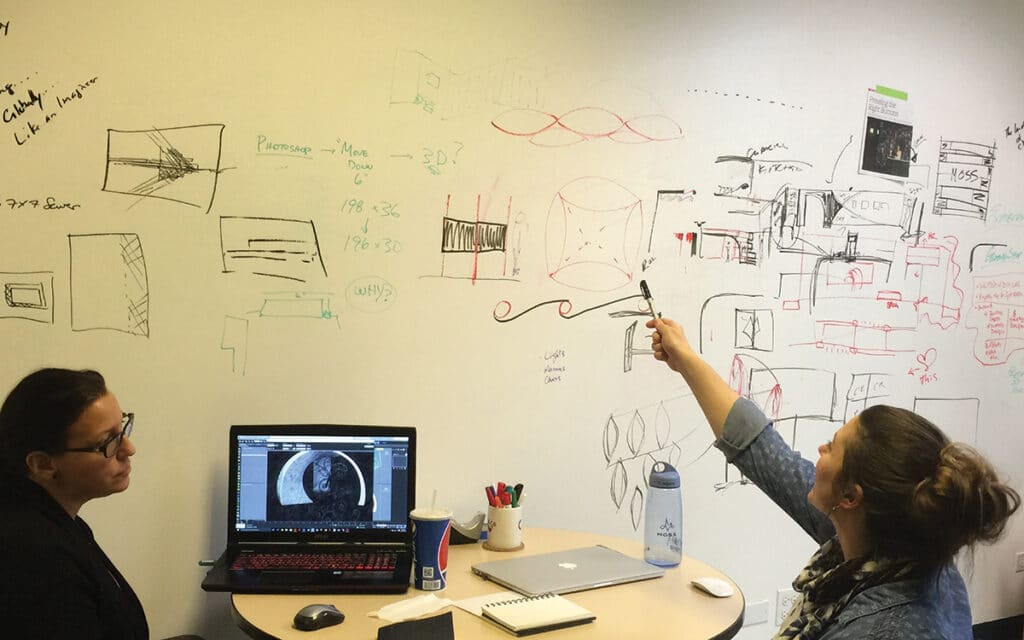

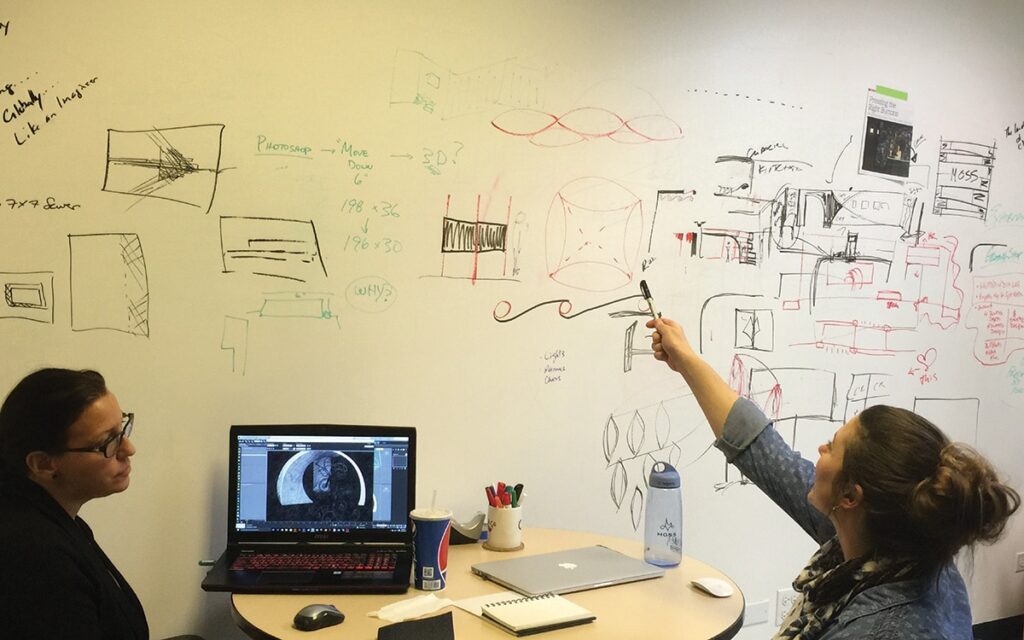

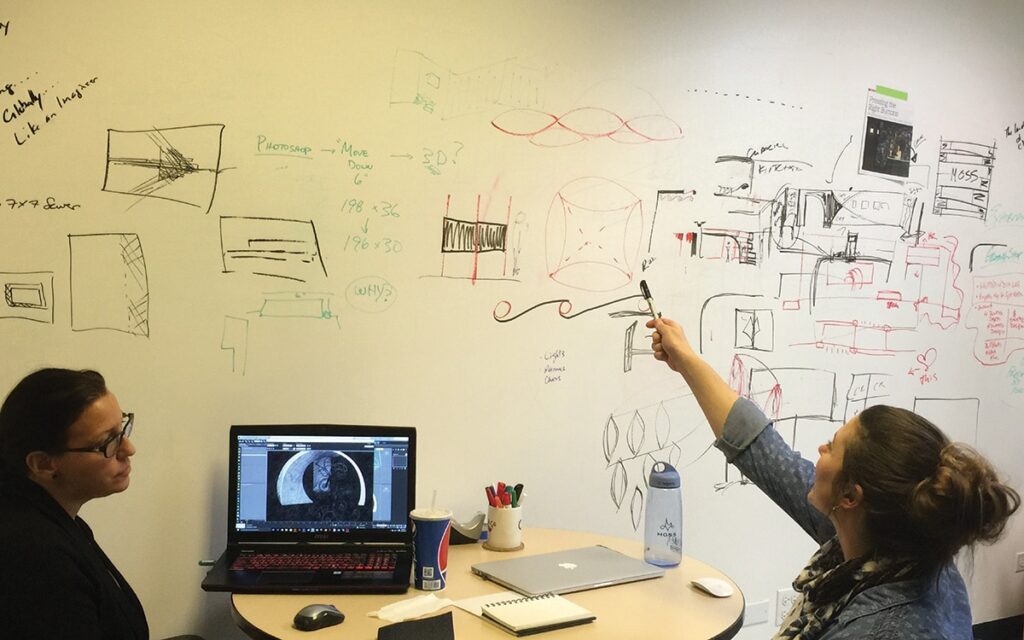

Our Creative Design Team executes environmental graphic design, conceptual 3D renderings, original content creation, graphic file manipulation, and animated content. These in-house creatives are fully trained on our production processes — so design for manufacturing is integrated into their services. If you’re outsourcing your design, outsource it to us, or contact us to schedule a designer-to-designer training session with your staff.

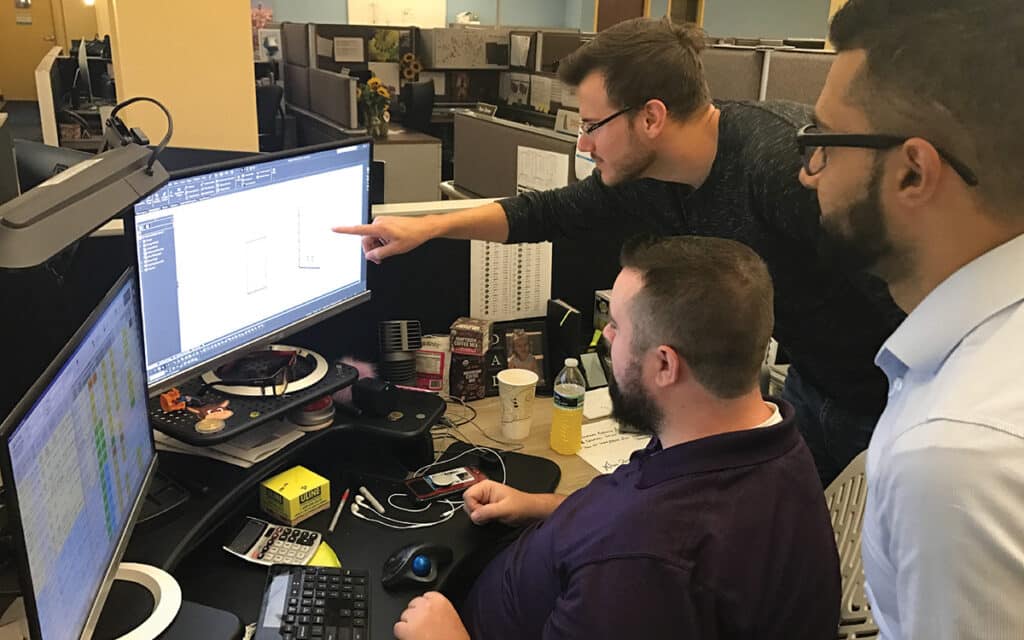

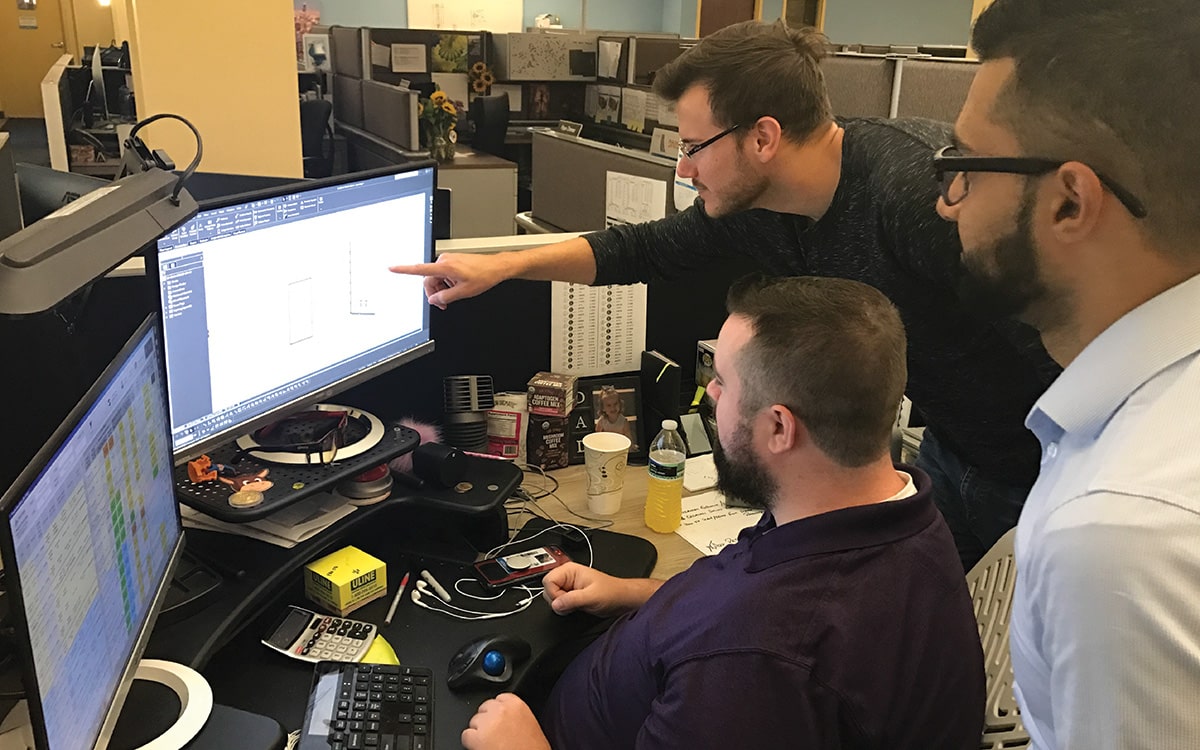

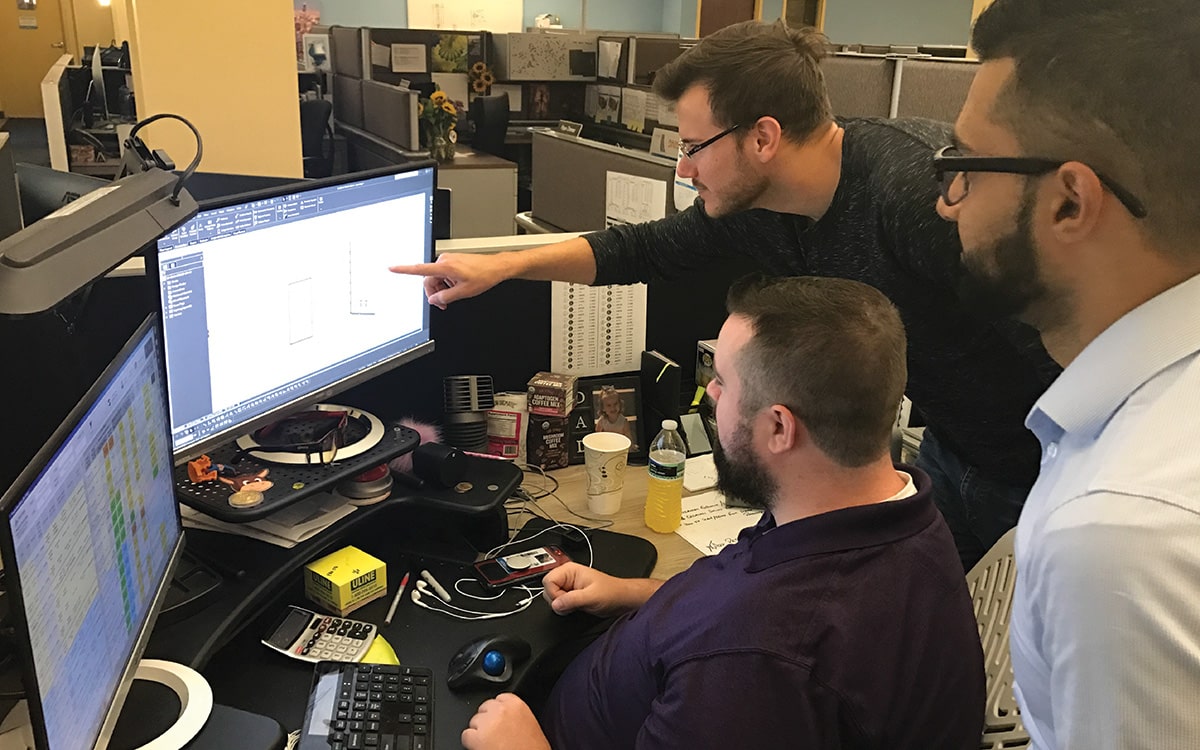

Our staff are cross-trained in handcraft and custom manufacturing and supported with the digitization that our Moss OS system provides.

This is the structure that allows us to integrate lighting, print, fabrication, paint and finishing into one project with optimum speed and impeccable quality — all within steps of your account team.

Our installers are project-informed and detail-oriented with global experience on all types of projects. We provide peace of mind for your installation anywhere you need us. We have experience working as self-contained installation teams and as supervisors directing labor personnel. This team has executed in just about any condition and is trained to remain professional with the client’s needs top of mind, in any situation.

- SOLUTIONS DESIGN+

- PROTOTYPING+

- DESIGN FOR MANUFACTURING+

- PRE-PRODUCTION+

- MANUFACTURING+

- INSTALLATION+

Our Creative Design Team executes environmental graphic design, conceptual 3D renderings, original content creation, graphic file manipulation, and animated content. These in-house creatives are fully trained on our production processes — so design for manufacturing is integrated into their services. If you’re outsourcing your design, outsource it to us, or contact us to schedule a designer-to-designer training session with your staff.

Our staff are cross-trained in handcraft and custom manufacturing and supported with the digitization that our Moss OS system provides.

This is the structure that allows us to integrate lighting, print, fabrication, paint and finishing into one project with optimum speed and impeccable quality — all within steps of your account team.

Our installers are project-informed and detail-oriented with global experience on all types of projects. We provide peace of mind for your installation anywhere you need us. We have experience working as self-contained installation teams and as supervisors directing labor personnel. This team has executed in just about any condition and is trained to remain professional with the client’s needs top of mind, in any situation.

ONLINE ORDERING

You’re connected—project information at your fingertips 24/7, get quotes, view project and shipping status, eliminate redundant phone calls and emails, visual merchandising, print management, upload art and print with one step—to us.

Moss is the most digitized partner in the industry. We invest in Moss OS as our proprietary, integrated solution to remain faster, more accurate, and easier for our customers to work with.

See how our digital connection can empower you. Click here.